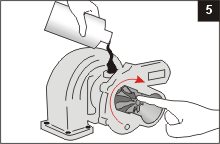

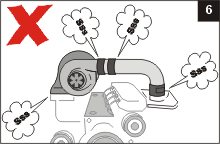

As a highly sophisticated piece of modern technology, a reconditioned turbo should be handled by professionals with extensive knowledge and experience in the subject of rebuilds and repairs. Any incorrect modifications introduced, mistakes made during installation (e.g. incorrectly connected pipes) might result in serious damage both to the turbine and the whole engine.

One of the crucial stages during turbo repairs is locating, diagnosing the reason of the part’s failure and eliminating it prior to installation.